high quality slurry pump wet end parts manufacturer

Latest articles

Dredge Pump

high quality slurry pump wet end parts manufacturer...

high quality slurry pump wet end parts manufacturer 【high quality slurry pump wet end parts manufacturer】

Read MoreSelecting a dredge pump

high quality slurry pump wet end parts manufacturer...

high quality slurry pump wet end parts manufacturer 【high quality slurry pump wet end parts manufacturer】

Read MoreIn AIER® slurry pumps, WY & WYJ sump pump are vertical centrifugal slurry pump, submerged for transfer abrasive, coarse particles and high density slurry. When working, it needs no seal water or any kind of seal. It can work well as well when suction volume is not enough.

high quality slurry pump wet end parts manufacturer...

high quality slurry pump wet end parts manufacturer 【high quality slurry pump wet end parts manufacturer】

Read MoreChoosing the right target=_blank title=Slurry Pump>slurry pump for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the target=_blank title=Slurry Pump Supplier>slurry pump supplier will share them with you.

high quality slurry pump wet end parts manufacturer...

high quality slurry pump wet end parts manufacturer 【high quality slurry pump wet end parts manufacturer】

Read MoreSlurry Pump Impeller Size

high quality slurry pump wet end parts manufacturer...

high quality slurry pump wet end parts manufacturer 【high quality slurry pump wet end parts manufacturer】

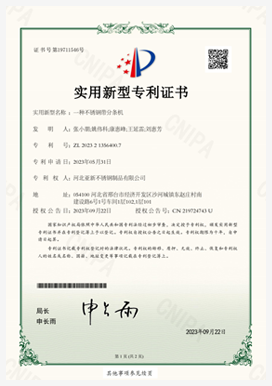

Read MoreThe Company Adopts Advanced Computer Aided Engineering Software

high quality slurry pump wet end parts manufacturer...

high quality slurry pump wet end parts manufacturer 【high quality slurry pump wet end parts manufacturer】

Read MoreWhy would maintenance personnel want to adjust a high-speed rotating impeller to a static lining component while the unit is running? Even if interlocking devices are used to prevent static and non-static components from coming into contact, how credible are these features and what are the implications for pump wear parts, bearings and motors if these two components come into contact?

high quality slurry pump wet end parts manufacturer...

high quality slurry pump wet end parts manufacturer 【high quality slurry pump wet end parts manufacturer】

Read MoreUnder ideal conditions, a dredge pump can produce fluid acceleration greater than the speed of its fastest moving component.

high quality slurry pump wet end parts manufacturer...

high quality slurry pump wet end parts manufacturer 【high quality slurry pump wet end parts manufacturer】

Read MoreSubmersible Slurry Pump

high quality slurry pump wet end parts manufacturer...

high quality slurry pump wet end parts manufacturer 【high quality slurry pump wet end parts manufacturer】

Read MoreIn addition, a new level of complexity is added to an otherwise simple machine. Other parts must now be inventoried and training beyond basic spanner turning is required. When it comes to pumping rock and some of the world's most abrasive materials.

high quality slurry pump wet end parts manufacturer...

high quality slurry pump wet end parts manufacturer 【high quality slurry pump wet end parts manufacturer】

Read More

Popular articles

- There are three different >types of slurry pump impellers; open, closed, and semi-open. Each has its own strengths and weaknesses, depending on the application. Some are better for solids handling, others are better for high efficiency.

- Are the pump discharge components suitable for the slurry being pumped?

- Slurry Pump

- Slurry pumps with rubber lining are the ideal pump for the mineral sand industry. They have a special rubber lining that makes them heavy duty pumps capable of withstanding high levels of abrasion.

- As the slurry is collected at the bottom of the tower, more rubber lined pumps are required to transfer the slurry to storage tanks, tailings ponds, waste treatment facilities or filter presses. Depending on the type of FGD process, other pump models are available for slurry discharge, pre-scrubber recovery and catch basin applications.

- 1.Find the spot that allows the pump to run as slow as possible (to reduce wear), but fast enough to keep solids from settling and clogging the lines.To reduce wear, lower the pump’s discharge pressure to the lowest point possible. Follow proper piping principles to ensure a constant and uniform delivery of the slurry to the pump.

Latest articles

-

A , slurry pump, is a special type of pump capable of handling slurry. Unlike water pumps, slurry pumps are prone to wear and tear and are more robust and durable.

-

Fewer and thicker vanes on the impeller. This makes it easier for solids to pass through than the 5-9 vanes on a standard centrifugal pump - typically 2-5 vanes.

-

Find the best position that allows the pump to run as slowly as possible (to reduce wear) but fast enough to prevent solids from settling and clogging the piping.

-

Dredge pumps are designed to transfer large quantities of fluids and solids.

-

Better safety

-

- Hydraulic efficiency is as important as the material, as efficiency is related to wear. The swept-back design of the impeller blades minimises the separation of solids from the carrying fluid, resulting in a more uniform flow. This results in a slower wear rate.

Links

- The striking red color of the pan not only livens up your kitchen but also adds a touch of drama to your dining table. It transforms cooking into an artistic endeavor, making meal preparation an enjoyable and visually appealing experience.

Enamel Pot Epoxy Repair:

High-heat cooking, searing, browning

Indoor Cast Iron Griddle are designed for use on the stovetop, making them ideal for cooking indoors. Indoor Cast Iron griddles are generally smaller in size and are ideal for cooking breakfast items like bacon, eggs, and pancakes. Indoor Cast Iron Griddle's compact design makes it easy to store and clean, making it a convenient addition to home kitchens.

Materials Used for Sizzling Plates:

- To clean a cast iron vegetable grill pan, avoid using soap as it can strip the pan's seasoning. Instead, use a brush or scraper to remove any food residue, and then wipe the pan clean with a paper towel. If necessary, you can rinse the pan with water, but be sure to dry it thoroughly and apply a thin layer of oil to prevent rusting.

- As the skillet does its work, it's important to remember the virtue of patience. Good things come to those who wait, and this is never truer than with skillet cooking. Rushing the process can lead to disaster - a charred exterior or an undercooked interior. But with care and time, the result is nothing short of magical.

- The Reversible Double Griddle A Versatile Culinary Tool for Effortless Cooking

- Maintenance of a cast iron flat top grill is relatively straightforward. It requires regular seasoning to keep its non-stick properties and prevent rust. With proper care, a cast iron grill can last for generations, becoming more seasoned and better performing over time.

- Overall, the black enamel stock pot is a must-have for any home cook. With its durability, even heat distribution, and stylish design, this cookware piece is sure to become a staple in your kitchen. Whether you're a seasoned chef or just starting out, the black enamel stock pot is a reliable and versatile tool that will help you create delicious meals for years to come.

The dual-riveted handle is long and made of the same material as the pan. The straight handle makes it easy to move the skillet and provides a secure grip. Some designs sport a grab handle on the front.

Stainless steel frying pans are also induction-ready. This means that they can be used on an induction cooker, which uses magnetic energy to heat the pan directly.

Flat bottom,Slope sides,No lids,Shallow depth.

It is important to consider the design of the pan when cooking specific food items, but generally, these pans are interchangeable.

skillet pan grill. It can be used on a variety of cooking surfaces, including gas stoves, electric stoves, and even outdoor grills. This makes it an excellent choice for those who want to grill indoors during the colder months or for those who want to take their grilling skills outdoors.

skillet pan grill. It can be used on a variety of cooking surfaces, including gas stoves, electric stoves, and even outdoor grills. This makes it an excellent choice for those who want to grill indoors during the colder months or for those who want to take their grilling skills outdoors. frying cast iron skillet. If it's too hot, your food will burn; if it's not hot enough, it won't fry properly. To test the oil's readiness, drop a small piece of bread or a kernel of popcorn into the oil – if it sizzles and browns within a few seconds, the oil is ready.

frying cast iron skillet. If it's too hot, your food will burn; if it's not hot enough, it won't fry properly. To test the oil's readiness, drop a small piece of bread or a kernel of popcorn into the oil – if it sizzles and browns within a few seconds, the oil is ready.

While it is also rare for skillets to come with a lid, you’ll certainly see it more often than you would on a frypan. The lid is also typically fully opaque so you won’t be able to monitor your cooking as easily. But it sure helps with slow-cooking and braising dishes.

Use a non-abrasive sponge or brush to gently scrub the paste into the pan, being sure to cover all areas Use a non-abrasive sponge or brush to gently scrub the paste into the pan, being sure to cover all areas

Use a non-abrasive sponge or brush to gently scrub the paste into the pan, being sure to cover all areas Use a non-abrasive sponge or brush to gently scrub the paste into the pan, being sure to cover all areas cleaning cast iron fry pan. Let the paste sit in the pan for about 15 minutes, then rinse it off with hot water. Baking soda is an excellent natural cleaner and will help to remove any stubborn stains or odors from your cast iron frying pan.

cleaning cast iron fry pan. Let the paste sit in the pan for about 15 minutes, then rinse it off with hot water. Baking soda is an excellent natural cleaner and will help to remove any stubborn stains or odors from your cast iron frying pan.Bread Baking: Dutch ovens are favored for baking artisanal bread due to their ability to create a steamy environment that results in a crispy crust and a soft interior.